Pulse welding is a variation on two core processes commonly taught in a welding training program.

Aluminum pulse mig welding settings chart.

In other words no matter how you set the controls the machine circuitry is rapidly making adjustments on the fly its not as simple as just setting voltage and wire speed.

Productivity increases with improved deposition rates using ac aluminum pulse gmaw waveform technology are.

The settings needed to mig weld aluminum are pretty much the same for all positions.

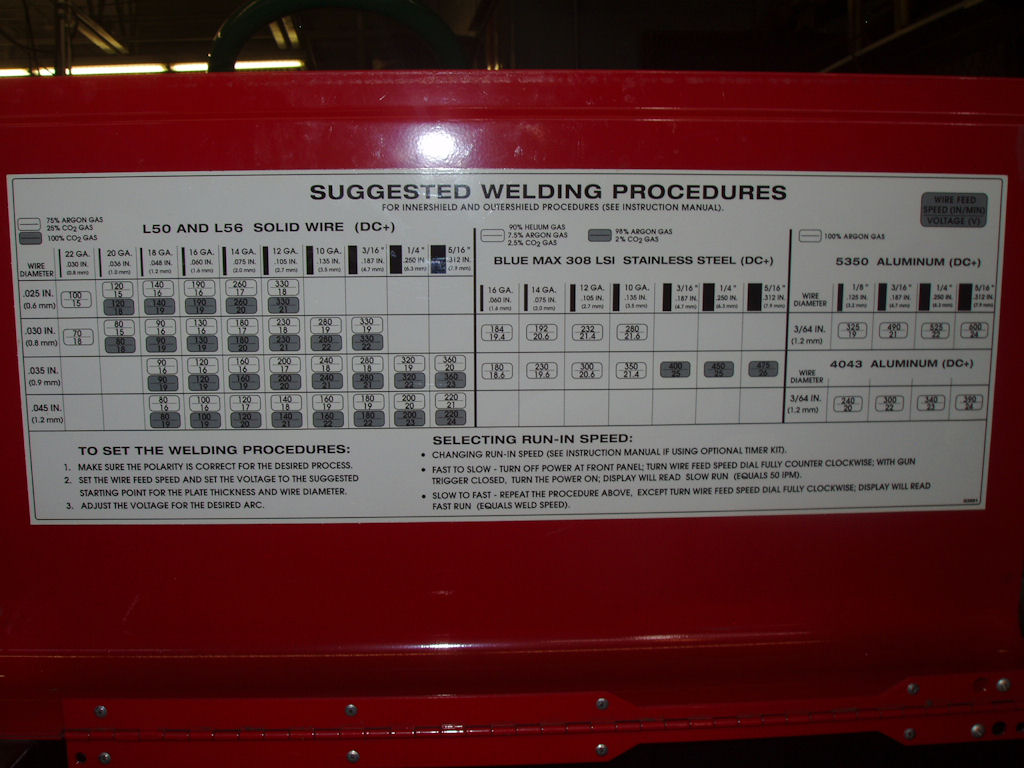

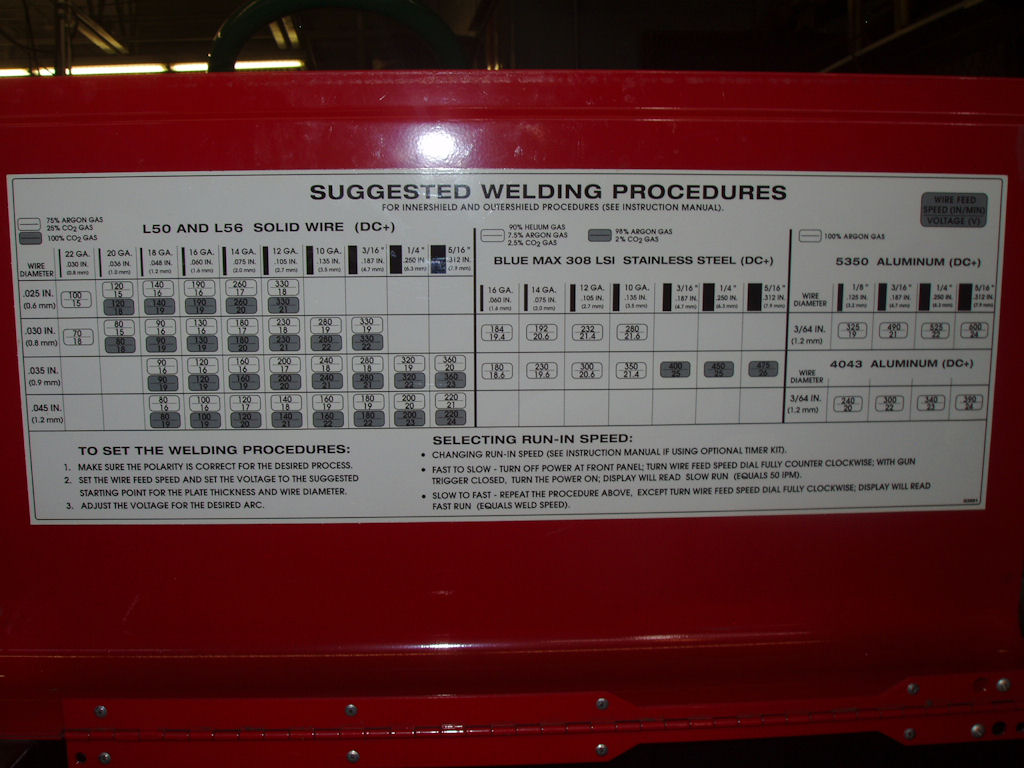

Lincoln mig welding aluminum setting chart aluminum mig welding settings.

For pulse settings set pulse width 60 peak current 185 background current 75 hz 1 0.

Mig welder settings charts guides and tables for steel stainless and aluminum lincoln mig welding electrode and gas selection chart settings.

In most cases it will take 21 to 23 volts to get the arc to spray transfer.

Ac aluminum pulse gmaw brings features that cannot be realized with standard dc pulse mig welding.

Good equipment makes mig welding easier while poor equipment can cost you dearly in frustration and weld quality.

Pulsed mig is beneficial on all aluminum applications.

Browse suggested weld parameter settings for stick welding tig welding mig solid wire welding and mig flux core welding.

When welding mild steel a good rule of thumb is to set the amperage level at 1 amp for every 0 001 of thickness.

If you re looking for a machine with multiple welding capabilities we recommend multiprocess welders like the multimatic 215 and multimatic 220 ac dc.

Metal thickness amperage settings.

Mig welding pulse settings are pretty confusing and one of the reasons is that a lot of mig welding machines capable of pulse settings use what is called a synergic control.

Over 0 100 traditional mig spray transfer is beneficial in contrast to mig welding steels the pulsed mig process provides real welding benefits.

For out of position mig welding pulse spray cannot be beat.

Gas metal arc welding mig and gas tungsten arc welding tig.

Mig welders such as the millermatic 211 and millermatic 141 are ideal for the occasional welder.

So if you are welding 12 gauge mild steel with a thickness of 0 100 you would set the machine at 100 amps.

The ac pulse process reduces the heat input by focusing the energy away from the base plate and switching the polarity of the arc.

For pulse settings set pulse width 60 peak current 125 background current 50 hz 1 0 3 16 1 4 pre flow 1 sec hot start 20 amperage 185 post flow 8 0 sec.

To start the pictures above and below are the manufacturer s recommended lincoln welders and miller welding equipment voltage wire feed speed settings and gas recommendations.